Haulotte Operators Manual Haulotte

. Operator's manual Operator's manual STAR 6 - STAR 13 24203 0 E 426500 E 02.16 USA / GB. STAR 6 - STAR 500 E 02.16 USA / GB. Operator's manual CONTENTS FOREWORD 1 - User responsibility. 1.1 - Owner's responsibility. 1.2 - Employer's responsibility. Operator's manual PRE-OPERATION INSPECTION 1 - Recommendations.2 - Working area assessment.3 - Inspection and Functional test.

Operator's manual 5.8 - Lifting operation.5.8.1 - Loading and unloading. Operator's manual. STAR 6 - STAR 13 - Foreword Foreword You have just purchased a HAULOTTE® product and we would like to thank you for your business. The Aerial Work Platform is a mechanical device primarily designed and manufactured with the intent to position people with the necessary tools and material to overhead elevated temporary workplaces.

STAR 6 - STAR 13 - Foreword 1 - User responsibility 1.1 - OWNER'S RESPONSIBILITY The owner (or hirer) has the obligation:. To inform operators of the instructions contained in the Operator's Manual. For applying the local regulations regarding operation of the machine. STAR 6 - STAR 13 - Foreword 1.4 - OPERATOR'S RESPONSIBILITY The operator has the obligation to:.

Read and understand the contents of this manual and familiarize himself with the decals affixed on the machine. To inspect the machine before use according to HAULOTTE®'s recommendations. STAR 6 - STAR 13 - Foreword 2 - Safety 2.1 - SAFETY INSTRUCTIONS 2.1.1 - Misuse Hazards. Do not use the machine for any other purpose than to position people, their tools and material to the overhead/elevated temporary work places.

STAR 6 - STAR 13 - Foreword 2.1.2 - Falling Hazards To enter or exit from the platform:. The machine must be completely stowed. Face the machine to access the entry opening to the platform. Keep 3 points of contact (both hands and a foot) on the steps and the guardrail. STAR 6 - STAR 13 - Foreword 2.1.3 - Overturning / Tip-over Hazards Before positioning and operating the machine:. Ensure that the surface is capable of supporting the machine weight including the rated capacity.

Check the load bearing capacity of the supporting ground. STAR 6 - STAR 13 - Foreword Using a machine on a slope Do not exceed the slope limit for each operation. Section B 4.1Technical specifications. While machine is on a slope, take extra precautions:. to make sure that the machine does not over steer. STAR 6 - STAR 13 - Foreword N.B.-:-The Beaufort scale of wind force is accepted internationally and is used when communicating weather conditions.

A wind speed range at 10 m (32 ft 9 in) above flat, clear land is associated with each degree. STAR 6 - STAR 13 - Foreword 2.1.4 - Electrocution Hazards The machine is not electrically insulated and does not provide protection from contact or proximity to electrically charged conductors. Always position the lift at a safe distance from electrically charged conductors to ensure that no part of the machine is within an unsafe area.

STAR 6 - STAR 13 - Foreword 2.1.5 - Explosion / Fire Hazards Always wear protective clothing and eye wear when working with batteries and power sources/systems. N.B.-:-Acid is neutralized with sodium bicarbonate and water. Do not work on or operate a machine in an explosive or flammable atmosphere / environment. STAR 6 - STAR 13 - Foreword.

When driving, position the platform so as to provide the best possible visibility and to avoid any blind spots. Hold on securely to the guardrails. Occupants must wear a fall arrest harness, with lanyard and energy absorber in accordance with governmental regulations. STAR 6 - STAR 13 - Foreword 3 - Safety inquiries Inquiries relating to design criteria/specifications of a product, standards compliance, or overall machine safety should be sent to the HAULOTTE® PRODUCT SAFETY department.

Each inquiry or request should include all relevant information; including contact name, telephone number, mailing address, email address, plus the machine model and serial number. STAR 6 - STAR 13 - Foreword 5 - Compliance 5.1 - PRODUCT INFORMATION Without the written permission from Haulotte, modifying a HAULOTTE® product is a Safety concern.

Any modification may violate Haulotte design parameters, government regulations and industry standards. Company stamp is mandatory: Tick here if the machine has been permanently removed from service (scrapped). The manufacturer's nameplate must be removed and returned to HAULOTTE Group when the unit is removed from service. Reason for removal: E 02.16.

STAR 6 - STAR 13 - Foreword 5.2 - PRODUCT SPECIFICATIONS HAULOTTE® cannot be held liable for any changes to the technical characteristics/ specifications contained in this manual. HAULOTTE® has a continuous improvement policy in place for its product range; given this policy, the Company reserves the right to modify their products technical characteristics / specifications without notice. STAR 6 - STAR 13 - Foreword Notes E 02.16 USA / GB.

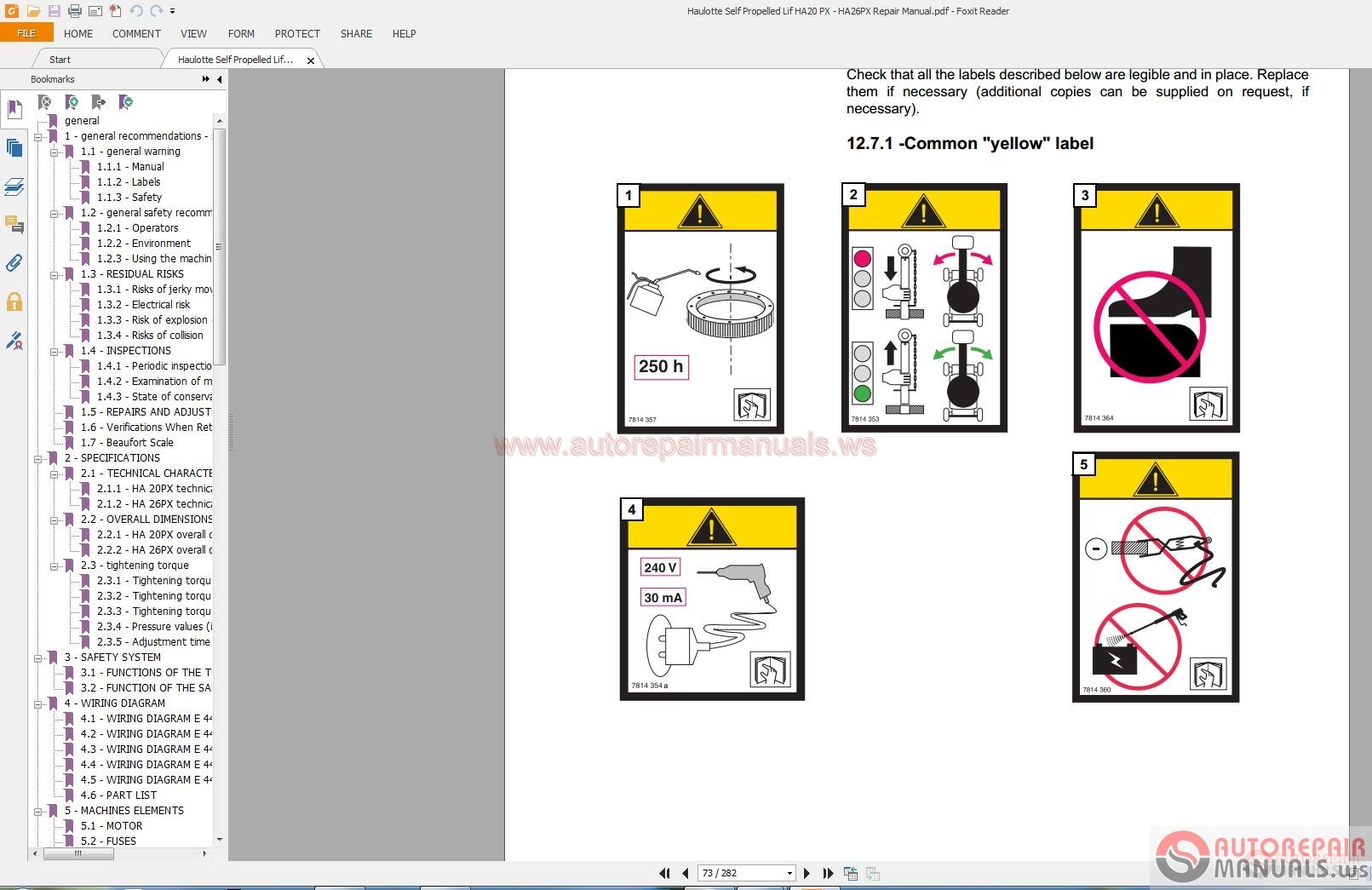

STAR 6 - STAR 13 - Familiarization Familiarization 1 - General safety 1.1 - INTENDED USE To ensure the safe use of an Aerial Work Platform, support personnel must always be available on the ground. If necessary, support personnel will be required to operate the emergency functions of the machine and in rescuing the operator. STAR 6 - STAR 13 - Familiarization 1.2 - DECAL CONTENT Decals are provided to alert the user of hazards inherent with the Aerial Work Platforms.

Decals provide the following information:. The level of severity. The specific hazard. STAR 6 - STAR 13 - Familiarization 1.3 - SYMBOLS AND COLORS Symbols and colors are used to alert the operator of safety precautions and/or to highlight important safety information.

The following safety symbols are used throughout this manual to indicate specific hazards and the hazard severity level when operating or maintaining the Aerial Work Platform. STAR 6 - STAR 13 - Familiarization 1.5 - SYMBOLS LEGEND AND DEFINITIONS Symbols are used throughout this manual to depict hazards, avoidance measures and indicate when information is required. Refer to the following table to familiarize yourself with these symbols.

STAR 6 - STAR 13 - Familiarization 2 - Models description Regulation Models ANSI and CSA standards STAR 13 CE and AS standards STAR 6 E 02.16 USA / GB. STAR 6 - STAR 13 - Familiarization 3 - Primary machine components 3.1 - LAYOUT STAR 6 - STAR 13 Marking Description Marking Description Chassis Pothole protection Platform Tilt sensor Platform control box Guardrail Tie-down (and/or forklift loading) Platform access step. STAR 6 - STAR 13 - Familiarization STAR 6 - STAR 13 with platform extension Marking Description Marking Description Chassis Tilt sensor Platform Extension deck Platform control box Guardrail Tie-down (and/or forklift loading) Platform access step Ground control box Sliding guardrail. STAR 6 - STAR 13 - Familiarization 3.2 - MAINTENANCE SUPPORT The maintenance stand must be in place before any maintenance operation is begun. Placing the machine in maintenance configuration:. Raise the telescoping mast upto 1,20 m (3 ft 11in).

STAR 6 - STAR 13 - Familiarization 3.3 - EXTENSION DECK (IF FITTED) N.B.-:-Do not load the extension deck, for ease of manoeuvring. Ensure that gate or sliding bar is in it’s proper closed position. Perform these operations on flat, horizontal ground. STAR 6 - STAR 13 - Familiarization 3.4 - GROUND CONTROL BOX 3.4.1 - Layout General view Controls and indicators Marking Description Function Pulled out: Ground control box energized E-stop button Pushed in: De-energizes control system Horn Horn button. STAR 6 - STAR 13 - Familiarization 3.4.2 - HAULOTTE Activ'Screen Upon starting and during operation of the machine, the LCD screen 'Activ'Screen' located on the ground control box displays in real time the machine operating status. HAULOTTE Activ'Screen Controls and indicators.

STAR 6 - STAR 13 - Familiarization 3.4.2.1 - LCD screen At startup At startup with the ground or platform controls selected; system initiates a self check:. Bar gets filled up. Home screen comes on with status icon of the machine - okay to proceed functioning the controls. STAR 6 - STAR 13 - Familiarization. Pressing either one of the buttons, the following screen shot will be displayed: Symbol Description Software part number Software version + Screen software version + Screen version Screen identification + Screen software version Machine serial number displayed. STAR 6 - STAR 13 - Familiarization Alarm status Alarm status displayed as applicable - samples shown below. Tilt.

Low battery E 02.16 USA / GB. STAR 6 - STAR 13 - Familiarization. Present fault.

Platform control box E-stop button pressed in (de-energized) E 02.16 USA / GB. STAR 6 - STAR 13 - Familiarization 3.5 - PLATFORM CONTROL BOX 3.5.1 - Layout General view 100% c E 02.16 USA / GB. STAR 6 - STAR 13 - Familiarization Controls and indicators Marking Description Function Tilt indicator Machine on excessive slope Overload indicator Not used Horn button Move upwards and hold to activate horn Pulled out: Platform control box power supply energized.

STAR 6 - STAR 13 - Familiarization 4 - Performance Specifications 4.1 - TECHNICAL CHARACTERISTICS Use the table to select the right Haulotte machine for the job. CE and AS standards Machine STAR 6 Characteristics - Dimensions Imp. Maximum working height. STAR 6 - STAR 13 - Familiarization Machine STAR 6 with platform extension Characteristics - Dimensions Imp. Maximum working height 5,80 m 19 ft 0 in Maximum platform height 3,80 m 12 ft 6 in Total weight 890 kg 1962 lbs.

STAR 6 - STAR 13 - Familiarization ANSI and CSA standards Machine STAR 13 Characteristics - Dimensions Imp. Maximum working height 5,80 m 19 ft 0 in Maximum platform height 3,80 m 12 ft 6 in Total weight 835 kg. STAR 6 - STAR 13 - Familiarization Machine STAR 13 with platform extension Characteristics - Dimensions Imp. Maximum working height 5,80 m 19 ft 0 in Maximum platform height 3,80 m 12 ft 6 in Total weight 890 kg 1962 lbs. STAR 6 - STAR 13 - Familiarization 4.2 - WORKING AREA / RANGE OF MOTION STAR 6 - STAR 13 ft in -6ft 6in -3ft 3in 3ft 3in 6ft 6in 19ft 8in 16ft 5in 13ft 10in 9ft 10in 6ft 6in.

STAR 6 - STAR 13 - Familiarization STAR 6 - STAR 13 with platform extension ft in -6ft 6in -3ft 3in 3ft 3in 6ft 6in 19ft 8in 16ft 5in 13ft 10in 9ft 10in 6ft 6in 3ft 3in -2 m -1 m E 02.16. STAR 6 - STAR 13 - Familiarization 5 - Decals and markings locations CE standard E 02.16 USA / GB. STAR 6 - STAR 13 - Familiarization CE standard Marking Color Description Quantity STAR 6 Height of the floor and load Blue Maximum Pressure per Tire - Floor Loading Other Commercial name - Bright machine Other Commercial name - Dark machine. Position of the lift truck forks Blue Transport height Other Electric traction Other 'Made in Europe' (1.) For STAR 6 with extension only (2.) For STAR 6 with extension only E 02.16 USA / GB. STAR 6 - STAR 13 - Familiarization Notes E 02.16 USA / GB. STAR 6 - STAR 13 - Familiarization AS standard E 02.16 USA / GB.

Transport height Other Electric traction Wearing a harness Do not travel down slopes in high speed (1.) For STAR 6 with extension only (2.) For STAR 6 with extension only E 02.16 USA / GB. STAR 6 - STAR 13 - Familiarization Russia and the Ukraine version E 02.16 USA / GB. STAR 6 - STAR 13 - Familiarization Russia and the Ukraine version Marking Color Description Quantity STAR 6 Height of the floor and load Blue Maximum Pressure per Tire - Floor Loading Other Commercial name - Bright machine. STAR 6 - STAR 13 - Familiarization Marking Color Description Quantity STAR 6 Yellow Vertical crushing of the body Blue Caution glasses 307P226670 (1.) For STAR 6 with extension only (2.) For STAR 6 with extension only E 02.16 USA / GB. STAR 6 - STAR 13 - Familiarization Notes E 02.16 USA / GB.

STAR 6 - STAR 13 - Familiarization ANSI and CSA standards E 02.16 USA / GB. STAR 6 - STAR 13 - Familiarization ANSI and CSA standards Marking Color Description Quantity STAR 13 In english: Height of the floor and load - Single load In french: machine In spanish: Blue. STAR 6 - STAR 13 - Familiarization Marking Color Description Quantity STAR 13 Blue Transport height Other Electric traction (1.) For STAR 13 with extension only (2.) For STAR 13 with extension only (3.) For STAR 13 with extension only E 02.16. STAR 6 - STAR 13 - Pre-operation inspection Pre-operation inspection 1 - Recommendations The owner, the site manager, the supervisor and the operator are all responsible to ensure the machine is fit for the work it is to perform; i.e. That the machine is suitable to carry out the work in complete safety and in compliance with this Operator's Manual. STAR 6 - STAR 13 - Pre-operation inspection 2 - Working area assessment To ensure safety during operation, the following should be considered:.

Segregate other site traffic (delivery vehicles, dumpers, etc) from the work area. Check the work area for localised features, e.g. Manholes, service ducts, potholes, etc.

STAR 6 - STAR 13 - Pre-operation inspection 3 - Inspection and Functional test 3.1 - DAILY INSPECTION Each day before the beginning of a new work session and with each change of operator, the machine must be subjected to a visual inspection and a complete functional test. STAR 6 - STAR 13 - Pre-operation inspection Daily inspection Visual inspection without Check level disassembly To check by test Corrected applicable Manuals and displays. Clean or replace if necessary. Presence, cleanliness and legibility of the manufacturer's plate Presence, cleanliness and legibility of operator's. STAR 6 - STAR 13 - Pre-operation inspection Entry bar/gate closes automatically and is not prevented from closing. The locking system of the deck extension functions properly Folding guard-rail (if fitted) is fixed securely in position Extending structure (jib, mast). STAR 6 - STAR 13 - Pre-operation inspection Energy storage and motorisation: tanks, batteries and engine Battery electrolyte level No screws missing / loose parts Presence and good condition of hydraulic hose Presence and good condition of engine components Presence and good condition of the batteries: terminations and clamps, electrolyte level.

STAR 6 - STAR 13 - Pre-operation inspection 4 - Safety functional checks To protect the user and the machine, safety systems prevent the movement of the machine beyond its operating limits. These safety systems when activated immobilize the machine and prevent further movement. STAR 6 - STAR 13 - Pre-operation inspection 4.2 - ACTIVATION OF CONTROLS The enable switch must be active to allow all movements.

The 'Enable Switch' system depends on the machine configuration and will consist of one of the following:. STAR 6 - STAR 13 - Pre-operation inspection 4.4 - SLOPE WARNING DEVICE From each control box, a buzzer alerts the operator that the machine is not folded/stowed and is positioned on a slope exceeding the slope allowed.

N.B.-:-The slope sensor is only active when the platform is not in the stowed position. STAR 6 - STAR 13 - Pre-operation inspection 4.6 - ELECTRONIC VARIABLE SPEED DRIVE The machine is equipped with 2 electronic variable speed regulators configured for each function that manages the amount of power sent to each motor. Do not interchange the speed controllers/regulators between machines even if they are the same model. STAR 6 - STAR 13 - Pre-operation inspection 4.9 - WHEEL MOTOR BRAKE RELEASE Each time a drive command is activated, electric power releases the brakes. 4.10 - POTHOLE PROTECTION SYSTEM To reduce the risk of overturning, the machine is equipped with a pothole mechanism under the chassis that is deployed automatically when the platform is out of the stowed position. STAR 6 - STAR 13 - Pre-operation inspection Notes E 02.16 USA / GB.

STAR 6 - STAR 13 - Operation instructions Operation instructions 1 - Operation 1.1 - INTRODUCTION Aerial Work platforms are equipped with two control boxes which allow operators to safely use the machine. An auxiliary device is available on the chassis to assist with the emergency rescue of people. STAR 6 - STAR 13 - Operation instructions A buzzer beeps in the following conditions:. Overload (if fitted). Machine out of stowed position and on a slope greater than allowable slope. Hydraulic oil overheating. Movements option.

STAR 6 - STAR 13 - Operation instructions 2 - Ground control box 2.1 - TO START AND STOP THE MACHINE. Pull the E-Stop button at the ground control box. Turn the control box activation selector key ( 92 ) downwards to activate the ground control box. STAR 6 - STAR 13 - Operation instructions 3 - Platform control box 3.1 - TO START AND STOP THE MACHINE To start the machine: At the ground control box:.

The E-stop button on the ground control box must be in ON position (pulled out / activated). STAR 6 - STAR 13 - Operation instructions 3.3 - MOVEMENT CONTROL To operate Mast Extension / Retraction function, move 2 position selector switch ( 112 ) to the left.

Activate mast extension / retraction switch ( 110 ). Simultaneously operate joystick ( 108 ) with joystick trigger (Enable switch ( 123 )) pressed in and maintained for desired extension/ retraction. STAR 6 - STAR 13 - Operation instructions 4 - Emergency procedure 4.1 - IN CASE OF POWER LOSS If an operating problem prevents the user on the platform from descending, a competent operator can do this from the chassis. STAR 6 - STAR 13 - Operation instructions 5 - Transportation 5.1 - PUTTING IN TRANSPORT POSITION To avoid any risk of machine movement during loading, ensure that:. The loading ramp can support the machine weight. The loading ramp is correctly attached to transport vehicle.

STAR 6 - STAR 13 - Operation instructions 5.3 - UNLOADING Before unloading, check that the machine is in good condition. Remove the tie downs. Switch the machine on. Move progressively the drive joystick (108). Warning: Upon starting a machine that has been secured and transported, the safety system may detect a false overload preventing all movement from the platform control box.

STAR 6 - STAR 13 - Operation instructions 5.4.1 - Electric brake release To tow a broken-down machine, the brakes can be released using the electric system. Perform these operations on flat, horizontal ground. Failing that, block the wheels to immobilize the machine.

STAR 6 - STAR 13 - Operation instructions 5.5 - STORAGE When the machine is in elevated position, it is necessary to regularly switch the power ON to ensure that the security systems are active. Machine must be parked in a protected/designated area with the mast fully retracted.

Make sure there is no load in the platform. STAR 6 - STAR 13 - Operation instructions 5.8 - LIFTING OPERATION 5.8.1 - Loading and unloading Before any lifting operation, it is necessary to take into account the following points: ONLY trained and authorized personnel should attempt to lift the machine. STAR 6 - STAR 13 - Operation instructions 5.8.1.4 - Procedure for the use of slings The machine must be completely stowed (Extension retracted). Designated lifting points are marked/labeled with the following symbol Position the spreader line up with the chassis. STAR 6 - STAR 13 - Operation instructions 5.9 - LOADING AND UNLOADING WITH FORKLIFT. Completely lower the mast. Ensure that the potholes are retracted.

The machine must be in the fully stowed transport position. Ensure that the machine controls are in the OFF position. STAR 6 - STAR 13 - Operation instructions 6 - Cold Weather Recommendations In extreme cold conditions, machines should be equipped with optional cold start kits. N.B.-:-Initial starting should always be performed from the ground control box.

6.1 - HYDRAULIC OIL External environmental conditions can reduce performance of the machine if the hydraulic oil temperature does not reach its optimum range. STAR 6 - STAR 13 - Operation instructions 7 - Battery care and maintenance 7.1 - BATTERY CHARGING Recharge aerial work platform batteries after each work shift or as needed. When the aerial work platform is not in use, batteries should be recharged at least once per week. Under normal circumstances, battery recharge should take approximately 8-10 hours. STAR 6 - STAR 13 - Operation instructions When should the batteries be charged?:. Never discharge the batteries to more than 80% of their capacity in 5 h (hours). When the batteries are discharged to between 35% and 80% of their nominal capacity.

STAR 6 - STAR 13 - Operation instructions To recharge the aerial work platform batteries: Attach a 12 AWG multi-strand, grounded extension cord with a maximum length of 15 m (50 ft) to the receptacle located on the charger. STAR 6 - STAR 13 - Operation instructions Notes E 02.16 USA / GB. STAR 6 - STAR 13 - General Specifications General Specifications 1 - Machine dimensions Stowed / Transport position: Configuration that takes the minimum floor space necessary for storage and / or delivery of the machine - Access position. CE and AS standards. STAR 6 - STAR 13 - General Specifications 2 - Major component masses N.B.-:-Masses measured with empty tanks. Component STAR 6 STAR 13 Frame assembly mass 328 kg 723 lbs Counterweight mass 118 kg 260 lbs Battery mass 60 kg. STAR 6 - STAR 13 - General Specifications 4 - Wheel/Tire assembly 4.1 - TECHNICAL SPECIFICATIONS Component Standard wheel Reference number Solideal Type Solid tires/tyres Size 318 mm / 108 mm (12,52 in/ 4,25 in) Torque 80 Nm (59 ft lbs) 4.2.

STAR 6 - STAR 13 - General Specifications Procedure of replacement:. Loosen the wheel nuts on the wheel to be removed.

Raise the machine using a jack or a hoist. Remove the wheel nuts. Remove the wheel.

STAR 6 - STAR 13 - Maintenance Maintenance 1 - General As an owner and/or operator of Haulotte equipment, your Safety is of utmost importance to HAULOTTE®, which is why HAULOTTE® places such a high priority on product safety. STAR 6 - STAR 13 - Maintenance 2 - Maintenance Schedule This section provides the necessary information needed to place the machine in safe operation. For maximum service life and safe operation, ensure that all the necessary inspections and maintenance have been completed. STAR 6 - STAR 13 - Maintenance 3 - Inspection program 3.1 - GENERAL PROGRAM The machine must be inspected on a regular basis at intervals of no less than once 1 per year. The purpose of the inspection is to detect any defect which could lead to an accident during routine use of the machine.

STAR 6 - STAR 13 - Maintenance 3.3 - PERIODIC INSPECTION The Periodic inspection is a thorough evaluation of the operation and safety features of the machine. It must be conducted before the sale / resale of the machine and/or at least once 1every year. STAR 6 - STAR 13 - Maintenance 4 - Repairs and adjustments Extensive repairs, interventions or adjustments on the safety systems or components must be performed by a HAULOTTE Services® technician. Use original spare parts and components only.

N.B.-:-HAULOTTE Services® technicians are trained professionals to perform extensive repairs, interventions and adjustments on the safety systems or components of HAULOTTE®. STAR 6 - STAR 13 - Maintenance Notes E 02.16 USA / GB. STAR 6 - STAR 13 - Other information Other information 1 - Warranty disclosure 1.1 - AFTER SALES SERVICE Our HAULOTTE Services® After Sales Service is at your disposal throughout your machine's service life to ensure the optimum use of your HAULOTTE product:. STAR 6 - STAR 13 - Other information 1.2.4 - Conditions of warranty HAULOTTE® guarantees its products against defects, faults or manufacturing defects when the owner or rental company has informed HAULOTTE® of the defect. The warranty does not cover the consequences of normal wear, nor any defects, failure.

STAR 6 - STAR 13 - Other information The present warranty does not cover damage that may result directly or indirectly from any flaws or defects covered by the latter:. Consumables: No claims will be accepted for objects or parts replaced in the context of normal machine usage. STAR 6 - STAR 13 - Other information 2 - Subsidiary contact information HAULOTTE FRANCE HAULOTTE INDIA PARC DES LUMIERES HAULOTTE ITALIA Unit No. 1205, 12th foor,Bhumiraj Costarica, 601 RUE NICEPHORE NIEPCE VIA LOMBARDIA 15 Plot No.

1&2, Sector 18. STAR 6 - STAR 13 - Other information For electric (battery operated) machines CALIFORNIA PROPOSITION 65 BATTERY WARNING Battery posts, terminals and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm.

STAR 6 - STAR 13 - Other information Notes E 02.16 USA / GB.

. OPERATOR’S & MAINTENANCE MANUAL B Rev 4 May 2013.

Repair or replace all damaged or malfunctioning components. Haulotte Group is dedicated to the continuous improvement of this and all Haulotte Group products. Therefore, equipment information is subject to change without notice. Direct any questions or concerns regarding errors and / or discrepancies in this manual to the Haulotte Group Customer Service Department: at 1-800-537-0540 or visit Haulotte Group online at www.haulotte-usa.com. HAULOTTE GROUP TABLE OF CONTENTS 1 SAFETY 7 LEGEND: SAFETY ADVISORIES.7 BEFORE OPERATION.8 DURING OPERATION.9 FALL PROTECTION.11 MANUAL FORCE.

11 WIND LOADING.12 EXPLOSION HAZARD.12 MAINTENANCE.13 2 SPECIFICATIONS. 15 RANGE OF MOTION. HAULOTTE GROUP DECAL KIT - AU.88 IDENTIFICATION PLATES & OPTIONAL EQUIPMENT – AU.90 7 OPTIONAL EQUIPMENT.93 DRIVE AND SET. 94 MATERIAL LIFT HOOK. 97 PLATFORM ROTATOR. 100 8 MATERIAL SAFETY.101 LEAD ACID BATTERIES, WET, FILLED WITH ACID – UN 2794.101 POWERFLOW™. HAULOTTE GROUP LIST OF ILLUSTRATIONS Figure 2-1.

Range of Motion. 15 Figure 3-1. Ground (Lower) Control Panel.22 Figure 3-2.

Platform (Upper) Control Panel.25 Figure 3-3. Boom Travel Latches. 28 Figure 3-4. Outrigger Control Panel.29 Figure 3-5. HAULOTTE GROUP PRIMARY MACHINE COMPONENTS PLATFORM JIB BOOM EXTENSION BOOM SECONDARY BOOM JIB LIFT CYLINDER SLAVE CYLINDER KNUCKLE MASTER CYLINDER SECONDARY LIFT CYLINDER PRIMARY BOOM SECONDARY BOOM REST LOWER LINK PRIMARY LIFT CYLINDER TURNTABLE GENERATOR INTERFACE PLATE JACK OUTRIGGER COUPLER. HAULOTTE GROUP 1 SAFETY 1 SAFETY Proper training is required for the safe operation of any mechanical device. Failure to follow all instructions and safety precautions in this manual and attached to the aerial work platform will result in death or personal injury.

Keep loose clothing, jewelry, gloves and hair away from moving parts. ALWAYS wear a Safety Harness and energy-absorbing Lanyard, such as the Safety Harness and Lanyard available through the Haulotte Group. ALWAYS inspect platform floor and outrigger footpads for mud, grease, debris or other foreign material.

HAULOTTE GROUP 1 SAFETY DURING OPERATION Ensure the following general safety precautions are followed while operating the aerial work platform: ALWAYS position away from power lines, this ensures that no part of the aerial work platform accidentally reaches into an unsafe area. This includes full extension of the telescoping boom through 700º. HAULOTTE GROUP 1 SAFETY DURING OPERATION (CONTINUED) ALWAYS use a three (3) point contact (both hands and one foot) when entering or exiting the work platform. ALWAYS wear proper footgear. ALWAYS keep the platform free of debris.

ALWAYS keep personnel and obstructions clear of the aerial work platform when repositioning the boom or platform. NEVER exceed the load limits set by the manufacturer / factory. Use only the material lifting hook, supplied as an option and manufactured by Haulotte Group when lifting materials. Safely stow all tools and equipment. NEVER exceed load ratings by transferring loads to the aerial work platform at elevated heights. HAULOTTE GROUP 1 SAFETY WIND LOADING Never operate the aerial work platform in strong or winds that exceed 28 mph (12.5 m/s) or 45 km/h). Never increase the surface area of the platform or the load.

Haulotte 2032e Operators Manual

Increasing the area exposed to the wind will decrease the aerial work platform stability. ALWAYS consult an authorized Haulotte Group technician by contacting the Customer Service Department: at 1-800-537-0540 if repairs are necessary. NEVER modify, alter or change the aerial work platform without first consulting an authorized Haulotte Group technician, and NEVER in any way that would affect its original design or operation. HAULOTTE GROUP 1 SAFETY MAINTENANCE (CONTINUED) Battery Maintenance Ensure the following general safety precautions are followed when performing battery maintenance on the aerial work platform: ALWAYS check the battery fluid level daily. ALWAYS wear safety glasses when working with or near batteries. HAULOTTE GROUP 2 SPECIFICATIONS 2 SPECIFICATIONS The following information is based on ideal working conditions.

Machine performance may vary based on work environment and on machine options. Only one boom function is permitted at a time, this function is only operable as long as the boom is within the safe operating zone. HAULOTTE GROUP 2 SPECIFICATIONS SPECIFICATIONS 41 ft 9 in (12.9 m) Maximum Working Height 35 ft 9 in (10.9 m) Maximum Platform Height 19 ft (5.8 m) Up and Over Height Maximum Horizontal Outreach From Centerline 22 ft 6 in (6.9 m) From Outrigger Footpad Edge 17 ft 5 in (5.3 m). HAULOTTE GROUP 2 SPECIFICATIONS SPECIFICATIONS (CONTINUED) 3,000 psi (207 bar) (20,684 kPa) Hydraulic Pressure 3.1 Gallons (11.7 L) Reservoir Capacity 5.1 Gallons (19.3 L) Hydraulic System Capacity HVI AW32 Hydraulic Oil (Standard) Maximum Decibel Level DC Mode – Ground (Lower) 60 dBA DC Mode –. HAULOTTE GROUP 2 SPECIFICATIONS WARRANTY - NEW PRODUCT; HAULOTTE NORTH AMERICA Haulotte US Inc (Haulotte) warrants its new products made by it to be free from defects in material or workmanship for twelve (12) months under normal operational conditions from the warranty start date (delivery date).

Haulotte Group BilJax to return warranty parts at the time the parts order is placed. 3) Replacement parts will then be sent by Haulotte Group BilJax to the dealer or distributor. All parts are invoiced at dealer distributor list price. DAMAGED EQUIPMENT POLICY Safety Statement At Haulotte Group we are dedicated to the safety of all users of our products. All Haulotte Group aerial work platforms are designed, manufactured and tested to comply with current applicable ANSI, CSA, AS and / or CE Standards and regulations. 3 OPERATION 3 OPERATION The 3522A / HTA 13 P Articulating Boom Lift is a Summit Series™ trailer-mounted aerial work platform, designed and manufactured to position personnel with their tools and equipment at overhead work locations. The platform load capacity is rated at 500 pounds (227 kilograms).

During all aerial work platform operations, four extended outriggers support the unit. HAULOTTE GROUP 3 OPERATION GROUND (LOWER) CONTROL PANEL The ground (lower) control panel is used to operate outriggers and all boom functions. To access the ground (lower) control panel, open the control panel access cover found on the turntable. The ground (lower) control panel includes the following controls and indicators. HAULOTTE GROUP 3 OPERATION GROUND (LOWER) CONTROL PANEL (CONTINUED) Display Panel is a lighted text window that displays the current operating status or an DISPLAY PANEL existing error condition when the (1) is positioned at either (1a) or (1b). HAULOTTE GROUP 3 OPERATION GROUND (LOWER) CONTROL PANEL (CONTINUED) Figure 3-1. Ground (Lower) Control Panel Auto Level LED When this LED is “FLASHING” it indicates that the booms are not in the “stowed” position, and the outriggers cannot be operated (non-functional).

When this LED is “ON SOLID” it indicates that the booms are in the “stowed”. HAULOTTE GROUP 3 OPERATION PLATFORM (UPPER) CONTROL PANEL The platform (upper) control panel is used to control all functions. The platform (upper) control panel is activated by turning the (1) on the ground (lower) control panel, clockwise to the KEY SWITCH (1b) icon. HAULOTTE GROUP 3 OPERATION PLATFORM (UPPER) CONTROL PANEL (CONTINUED) Figure 3-2.

Platform (Upper) Control Panel Battery Condition Indicator Indicator LEDs light up to indicate the level of charge in the batteries. A lighted green LED indicates an adequate charge level. HAULOTTE GROUP 3 OPERATION PLATFORM (UPPER) CONTROL PANEL (CONTINUED) 7-8. Boom Rotation Buttons Pressing (pushing) in and holding a desired (6) button and the SPEED BOOM ROTATION button at the same time enables the boom to rotate in the direction. HAULOTTE GROUP 3 OPERATION NORMAL OPERATING PROCEDURE Become familiar with the location and function of all controls. Learn to smoothly START STOP boom functions.

Perform the following procedures to operate the Haulotte Articulating Boom Lift. Read and obey all safety precautions and operating instructions, as well as all Federal, State, and .

HAULOTTE GROUP 3 OPERATION NORMAL OPERATING PROCEDURE (CONTINUED) Become familiar with the location and function of all controls. Learn to smoothly START STOP boom functions. At the ground (lower) control panel, turn the (1) counter clockwise to the KEY SWITCH GROUND (1a) icon. HAULOTTE GROUP 3 OPERATION NORMAL OPERATING PROCEDURE (CONTINUED) Use the ground (lower) control panel to operate the boom lift functions. Raise, lower, extend and rotate the booms by pressing (pushing) and holding the desired and function buttons at the SPEED same time. HAULOTTE GROUP 3 OPERATION MANUAL BOOM OPERATION Manual retraction, rotation and lowering functions allow the booms to be moved and lowered during hydraulic power interruption or failure. The following procedures for manual retraction, rotation and lowering require a person on the ground to operate the manual controls and hand pump.

HAULOTTE GROUP 3 OPERATION MANUAL BOOM OPERATION (CONTINUED) Manual Boom Lowering Procedure Each lift cylinder is equipped with a, found at the base of each lift cylinder. MANUAL LOWERING VALVE Use the to lower the platform in case of a complete electrical power failure, a load shift, or any VALVE other emergency.

HAULOTTE GROUP 3 OPERATION TOWING THE AERIAL WORK PLATFORM The aerial work platform trailer includes a single axle, two-inch ball hitch, hydraulic surge brakes, mechanical parking brake, safety chains, brake lights and side marker lights. Proper aerial work platform transport requires the proper inspection and attachment of these components before towing. HAULOTTE GROUP 3 OPERATION TOWING THE AERIAL WORK PLATFORM (CONTINUED) Procedure to hitch and tow the aerial work platform. Back the tow vehicle to the trailer. Verify that the ball and trailer hitch are aligned and that the trailer hitch has proper clearance above the ball.

HAULOTTE GROUP 3 OPERATION LIFTING THE AERIAL WORK PLATFORM Refer to Figure 3-9. Completely lower and retract all booms into the “stowed” position. Secure both boom travel latches (A). Remove all loose materials from machine. Retract all outriggers cylinders to fully “stowed” (upright) position. HAULOTTE GROUP 3 OPERATION TRANSPORTING THE AERIAL WORK PLATFORM ON A TRUCK BED Refer to Figure 3-10.

Verify that the truck or trailer is parked on a firm and level surface. Completely retract and lower all booms into the “stowed” position. Refer to it when inspecting this machine. It is the practice of Haulotte Group to issue Service and / or Safety Bulletins, which may include updates to the information contained in this manual. In such instances, procedures contained in Haulotte Group Service Bulletins or Safety Bulletins supersede the information contained in manual. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE BATTERY RECHARGE Recharge aerial work platform batteries after each 8-hour work shift or as needed. When the aerial work platform is not in use, batteries should be recharged at least once per week.

Under normal circumstances, battery recharge should take approximately 10-12 hours. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE BATTERY RECHARGE (CONTINUED) If a Battery fault is detected, a fault code will appear on the display. The red CHARGE CURRENT indicator LED will become lit. Refer to Table 4-1 for battery charger fault codes. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE DAILY SERVICE CHECKS The following Maintenance Procedures should be performed daily or before each operation: Verify that all decals are legible, correctly applied, and in plain view. Refer to the “Decal Replacement” section of this manual for decal locations.

HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE DAILY SERVICE CHECKS (CONTINUED) Verify that outrigger safety interlocks operate correctly. Begin with the outriggers fully extended and the aerial work platform leveled. Raise one outrigger until the footpad is not in contact with the ground. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE DAILY SERVICE CHECKS (CONTINUED) Inspect Hydraulic System and Fluid Levels. Check all hydraulic hoses and fittings for leaks and / or damage. Tighten or replace as necessary to prevent hydraulic oil or pressure loss. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE WEEKLY SERVICE CHECKS Perform the following service checks at least once each week in addition to all recommended Daily Service Checks: Check Battery Electrolyte level.

If battery charge is low, add enough water to bring the electrolyte level to the top of the plates. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE MONTHLY SERVICE CHECKS Perform the following service checks at least once each month: Check battery for loose connections or damaged wires. Clean all battery terminals. Verify proper operation of manual lowering valves and hand pump.

HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE ANNUAL SERVICE CHECKS Perform the following service checks at least once each year: Replace Hydraulic Oil and Oil Filter. Wipe away dirt and excess oil from the area around the power unit, hoses and filter(s) using cleaning cloths and alcohol solvent. 0.25 in (6.35 mm) the slew ring bearing should be replaced. Contact Haulotte Group Customer TAKE Service Department: at 1-800-537-0540 MEASUREMENT HERE or visit Haulotte Group online at www.haulotte-usa.com for additional information.

GROUND LEVEL Figure 4-8. Platform Position After Rotation. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE STRUCTURAL INSPECTION A comprehensive structural inspection of the unit shall be performed under any of the following conditions: Ten years from the date of manufacture and every five years thereafter.

After any actual, suspected or potential damage is sustained that could affect the structural integrity or stability of the aerial work platform. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE LEVELING SYSTEM CALIBRATION PROCEDURE Machine Leveling Instructions Deploy all of the outriggers, and slightly raise the base of the machine to position it for leveling. Refer to Figure 4-9. Place a small, standard “level” on the base of the turntable (Level Placement Option A).

If a small “level”. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE LEVELING SYSTEM CALIBRATION PROCEDURE (CONTINUED) Ground (Lower) Control Box Calibration Instructions Use the ground (lower) control panel to access the control box maintenance menu. Refer to Figure 4-12 Figure 4-12. Ground (Lower) Control Panel for Leveling System.

HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE OVERLOAD PROTECTION CALIBRATION PROCEDURE Load Sense Zeroing 1) Remove the securing the to the, allowing CLEVIS PIN PLATFORM PLATFORM MOUNTING BRACKET to pivot about the and rest on the ground. This removes the load.

HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE OVERLOAD PROTECTION CALIBRATION PROCEDURE (CONTINUED) 5) Scroll through the maintenance menu using the (3) button to scroll down, use the TURTLE RABBIT (5) button to scroll back up, until “Load Sense Zero Calibration Utility” is found. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE ADDITIONAL SERVICE INFORMATION Seals on hydraulic cylinders should be replaced every five years or as indicated by aerial work platform performance. All service checks should be performed on an aerial work platform that has been stored without use for a period exceeding thirty (30) days.

HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE MANUAL OUTRIGGER RETRACTION The Manual Outrigger Retraction procedure allows the outriggers to be retracted into the “stowed” (upright) position during hydraulic power interruption or power failure. The Manual Outrigger Control Kit, Part Number: A-00819, including a wire harness, is required to perform this manual procedure. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE HYDRAULIC PRESSURE GAUGE The Hydraulic Pressure Gauge Part Number B is used to measure the aerial work platform’s system pressure.

It is used as a diagnostic tool when the Boom is NOT performing as expected. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TROUBLESHOOTING Refer to the following Table for basic Troubleshooting Operations. Contact Haulotte Group Customer Service Department: at 1-800-537-0540 or visit Haulotte Group online at www.haulotte-usa.com with any questions or before attempting any advanced troubleshooting operations. If an error condition is detected, the appropriate error code will be displayed on this panel. Refer to Table 4-3 to resolve the error, or contact Haulotte Group Customer Service Department: at 1-800-537-0540 or visit Haulotte Group online at www.haulotte-usa.com. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TABLE 4-3 ERROR CODE DEFINITIONS ERROR MESSAGE ERROR DEFINITION TO SIMULATE ERROR TO CLEAR ERROR COMMENTS 013 PRESSURE Pressure sensor output Disconnect Pressure This is a self clearing Machines with Moment SENSOR IS is out of range Sensor error.

HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TABLE 4-3 ERROR CODE DEFINITIONS ERROR MESSAGE ERROR DEFINITION TO SIMULATE ERROR TO CLEAR ERROR COMMENTS 027 OPEN CIRCUIT A load of less than 70mA Disconnect a wire from This is a latched error. Checked only. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TABLE 4-3 ERROR CODE DEFINITIONS ERROR MESSAGE ERROR DEFINITION TO SIMULATE ERROR TO CLEAR ERROR COMMENTS 043 OPEN CIRCUIT A load of less than 70mA Disconnect a wire from This is a latched error. Checked only. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TABLE 4-3 ERROR CODE DEFINITIONS ERROR MESSAGE ERROR DEFINITION TO SIMULATE ERROR TO CLEAR ERROR COMMENTS 058 SHORTED CIRCUIT Excessive load was Use a piece of wire to This is a latched error. Checked only. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TABLE 4-3 ERROR CODE DEFINITIONS ERROR MESSAGE ERROR DEFINITION TO SIMULATE ERROR TO CLEAR ERROR COMMENTS 073 OPEN CIRCUIT A load of less than 70mA Disconnect a wire from This is a latched error.

HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TABLE 4-3 ERROR CODE DEFINITIONS ERROR MESSAGE ERROR DEFINITION TO SIMULATE ERROR TO CLEAR ERROR COMMENTS 088 SHORTED CIRCUIT Excessive load was Use a piece of wire to This is a latched error. Checked only. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TABLE 4-3 ERROR CODE DEFINITIONS ERROR MESSAGE ERROR DEFINITION TO SIMULATE ERROR TO CLEAR ERROR COMMENTS 103 OUTREACH Boom has exceeded Put 500lbs in boom, level This is a self clearing Machines with Moment NEAR MAXIMUM. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TABLE 4-3 ERROR CODE DEFINITIONS ERROR MESSAGE ERROR DEFINITION TO SIMULATE ERROR TO CLEAR ERROR COMMENTS 128 SHORTED CIRCUIT Excessive load was Use a piece of wire to This is a latched error.

Checked only. HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TABLE 4-3 ERROR CODE DEFINITIONS ERROR MESSAGE ERROR DEFINITION TO SIMULATE ERROR TO CLEAR ERROR COMMENTS 143 OPEN CIRCUIT A load of less than 70mA Disconnect a wire from This is a latched error. Checked only.

HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TABLE 4-3 ERROR CODE DEFINITIONS ERROR MESSAGE ERROR DEFINITION TO SIMULATE ERROR TO CLEAR ERROR COMMENTS 158 SHORTED CIRCUIT Excessive load was Use a piece of wire to This is a latched error. Checked only. Refer to Figure 4-15. Refer to Figure 4-15 for a visual of the controller. Refer to Table 4-4 to resolve the Fault, or contact Haulotte Group Customer Service Department: at 1-800-537-0540 or visit Haulotte Group online at www.haulotte-usa.com with any questions.

HAULOTTE GROUP 4 EQUIPMENT MAINTENANCE TABLE 4-4. ERROR CODE DEFINITIONS - MOTOR CONTROLLER FLASH PRIORITY ID FAULT DESCRIPTION SOLUTION FAULT Line Contactor did Line contactor did not close or is Check line contactor wiring and Molex not Close otherwise open circuit. Perform all maintenance procedures only in an area that is well-lit and well-ventilated. Haulotte Group is not responsible for personal injury or property damage resulting from the improper use of equipment or failure to follow all procedures and related safety precautions.

HAULOTTE GROUP 5 CYLINDER REPLACEMENT MASTER / SLAVE CYLINDER REPLACEMENT (CONTINUED) Master Cylinder (Continued) Place absorbent cloths below the cylinder ports and detach hydraulic hoses from the cylinder. Elevate hoses to prevent leakage. Plug or cap exposed hose fittings and cylinder ports. 5 CYLINDER REPLACEMENT LIFT CYLINDER REPLACEMENT 3522A / HTA 13 P Aerial Work Platforms have three (3) lift cylinders, use the following procedure to remove and replace faulty or damaged hydraulic cylinders. Refer to Figure 5–3 for the location of these cylinders.

HAULOTTE GROUP 5 CYLINDER REPLACEMENT LIFT CYLINDER REPLACEMENT (CONTINUED) Verify that the cylinder is supported by lifting straps and an overhead hoist or equivalent. Remove the pivot pin using a hammer and a brass or hardwood drift. HAULOTTE GROUP 5 CYLINDER REPLACEMENT OUTRIGGER CYLINDER REPLACEMENT Use the following procedure to remove and replace faulty or damaged hydraulic cylinders on the outriggers: Lower the outrigger until the footpad is touching the ground. DO NOT transfer the weight of the aerial work platform onto the outrigger. HAULOTTE GROUP 5 CYLINDER REPLACEMENT OUTRIGGER CYLINDER REPLACEMENT (CONTINUED) At the base of the cylinder, unbolt and remove the pin retainer from each side of the pivot pin. Remove the pivot pin using a hammer and a brass or hardwood drift. HAULOTTE GROUP 6 DECAL REPLACEMENT 6 DECAL REPLACEMENT WARNING Decals contain information that is required for the safe and proper use of the aerial work platform.

Decals should be considered necessary components of the machine and should be checked before each use to verify that they are correctly attached and legible. HAULOTTE GROUP 6 DECAL REPLACEMENT DECAL KIT - ANSI. Decal - Warning - Fork Lift Use B Decal - 3522A Transfer - Black B Decal - Caution - Transport Latch B Decal - Notice - Range of Motion - 3522A B Decal - Danger - Electrocution B Decal - 'Lubricate Semi - Annually' B. HAULOTTE GROUP 6 DECAL REPLACEMENT IDENTIFICATION PLATES & OPTIONAL EQUIPMENT - ANSI. HAULOTTE GROUP 6 DECAL REPLACEMENT IDENTIFICATION PLATES & OPTIONAL EQUIPMENT – ANSI IDENTIFICATION PLATES (Used on all standard equipment) ITEM NO. PART NUMBER DESCRIPTION QTY.

Haulotte Operator Manual

B Key Ring Tag B Annual Inspection Plate B VIN Plate B ANSI ID Plate REPLACEMENT DECALS FOR OPTIONAL EQUIPMENT –. HAULOTTE GROUP 6 DECAL REPLACEMENT DECALS - ANSI B B B B BB B B B B 3522A / HTA 13 P 0202-0523 B. HAULOTTE GROUP 6 DECAL REPLACEMENT DECALS – ANSI (CONTINUED) B B B B. HAULOTTE GROUP 6 DECAL REPLACEMENT DECALS – ANSI (CONTINUED) B B B B B B B B B B B B B B B B.

HAULOTTE GROUP 6 DECAL REPLACEMENT DECALS – ANSI (CONTINUED) B B8 B B B B B B B B B B B B B B B. HAULOTTE GROUP 6 DECAL REPLACEMENT DECAL KIT - CE. B-CE Decal - HTA 13 P - Black Clear Vinyl with Black Letters B-CE Decal - Notice - Range of Motion - 3522A B-DU DECAL KIT - Dutch - Includes the following: B-EN DECAL KIT - English International - Includes the following. HAULOTTE GROUP 6 DECAL REPLACEMENT IDENTIFICATION PLATES & OPTIONAL EQUIPMENT - CE. HAULOTTE GROUP 6 DECAL REPLACEMENT IDENTIFICATION PLATES & OPTIONAL EQUIPMENT - CE IDENTIFICATION PLATES (Used on all standard CE equipment) ITEM NO.

PART NUMBER DESCRIPTION QTY. B-CE ID Plate B VIN Plate DECALS FOR OPTIONAL EQUIPMENT - CE ITEM NO. HAULOTTE GROUP 6 DECAL REPLACEMENT DECAL KIT - AU.

DESCRIPTION QTY. B-CE Decal - HTA 13 P - Black Clear Vinyl with Black Letters B-CE Decal - Notice - Range of Motion - 3522A B- EN DECAL KIT - English International - Includes the following: ITEM NO. PART NUMBER DESCRIPTION QTY.

HAULOTTE GROUP 6 DECAL REPLACEMENT IDENTIFICATION PLATES & OPTIONAL EQUIPMENT – AU. HAULOTTE GROUP 6 DECAL REPLACEMENT IDENTIFICATION PLATES & OPTIONAL EQUIPMENT - AU IDENTIFICATION PLATES (Used on all standard equipment) ITEM NO. PART NUMBER DESCRIPTION QTY. B Annual Inspection Plate B VIN Plate B ANSI ID Plate REPLACEMENT DECALS FOR OPTIONAL EQUIPMENT - AU ITEM NO. HAULOTTE GROUP 6 DECAL REPLACEMENT. 7 OPTIONAL EQUIPMENT 7 OPTIONAL EQUIPMENT The Haulotte Model 3522A HTA 13 P is a Summit Series™ trailer-mounted aerial work platform that may be may be equipped with one or more optional components designed for the convenience and safety of operators when using the equipment to accomplish specific tasks. HAULOTTE GROUP 7 OPTIONAL EQUIPMENT DRIVE AND SET The Drive and Set Option allows the operator to drive the aerial work platform over a short distance on level ground, deploy, retract and level the outriggers from the platform (upper) control panel.

The platform (upper) control panel, which has additional controls added, is used to control all boom motions, as well as all Drive and Set functions. HAULOTTE GROUP 7 OPTIONAL EQUIPMENT DRIVE & SET CONTROLS (CONTINUED) Drive Enable Button. Press (push) in and hold the (2) button to activate the (1). To stop, release DRIVE ENABLE JOYSTICK either the (2) button or the (1). DRIVE ENABLE JOYSTICK Diagnostic Indicators. HAULOTTE GROUP 7 OPTIONAL EQUIPMENT DRIVE AND SET USE (CONTINUED) During Operation Utilize the Drive and Set option to advance to the next work location. Use the following procedure to operate the Drive and Set option.

Completely lower the platform into its “stowed” position. HAULOTTE GROUP 7 OPTIONAL EQUIPMENT MATERIAL LIFT HOOK If an aerial work platform is equipped with the Material Lift Hook option, several steps need to be performed to change from the Platform to the Lift Hook.

Use the follow procedure to make this change. HAULOTTE GROUP 7 OPTIONAL EQUIPMENT MATERIAL LIFT HOOK (CONTINUED) Insert the from the platform (upper) control panel into the receptacle on the bottom right of the PLUG ground (lower) control box (replacing the from the previous step). LOOPBACK PLUG . HAULOTTE GROUP 7 OPTIONAL EQUIPMENT MATERIAL LIFT HOOK (CONTINUED) On the ground (lower) control panel, turn the key switch (1) clockwise to the platform control (1b) icon. This provides for optimal control of the lift by using the platform (upper) control panel, and also allows for remote access. HAULOTTE GROUP 7 OPTIONAL EQUIPMENT PLATFORM ROTATOR The optional platform rotator allows the operator to rotate the elevated work platform 90º around a vertical axis by actuating a rotator handle found below the platform control panel.

Refer to Figure 6-2. The following Material Safety Data Sheets describe the correct procedures for the safe handling of chemical components within the Model 3522A HTA 13 P Articulating Boom Lift, as well as any potential health and safety hazards related to these chemicals. Material Safety Data Sheets are included here in accordance with applicable federal and state regulations. HAULOTTE GROUP 8 MATERIAL SAFETY MATERIAL SAFETY DATA SHEET LEAD ACID BATTERIES, WET, FILLED WITH ACID - UN 2794 (CONT.).

HAULOTTE GROUP 8 MATERIAL SAFETY MATERIAL SAFETY DATA SHEET LEAD ACID BATTERIES, WET, FILLED WITH ACID-UN 2794 (CONT.). HAULOTTE GROUP 8 MATERIAL SAFETY MATERIAL SAFETY DATA SHEET LEAD ACID BATTERIES, WET, FILLED WITH ACID - UN 2794 (CONT.). HAULOTTE GROUP 8 MATERIAL SAFETY MATERIAL SAFETY DATA SHEET LEAD ACID BATTERIES, WET, FILLED WITH ACID - UN 2794 (CONT.). HAULOTTE GROUP 8 MATERIAL SAFETY MATERIAL SAFETY DATA SHEET POWERFLOW™ AW HVI HYDRAULIC OIL.