Yia York Absorption Chiller Service Manual

TABLE OF CONTENTS INTRODUCTION RELIABILITY FEATURES HOW IT WORKS CONTROL SYSTEM MECHANICAL SPECIFICATIONS OPTIONAL FEATURES APPLICATION DATA RATINGS NOZZLE ARRANGEMENTS PHYSICAL DATA ELECTRICAL DATA GUIDE SPECIFICATIONS LIST OF ILLUSTRATIONS FIG. PAGE 1 Millennium Single-Stage Absorption Chiller Features 2 Standard Steam / Hot Water Cycle Diagram 3 Millennium Control Center 4 Typical Steam Piping 5 System 1: Atmospheric Condensate Return System 6 System 2: Vacuum Condensate Return System 7 System 3: Vacuum Condensate Return System with Steam Inlet and Condensate Outlet Under Vacuum 8 Typical Hot Water Piping 9 Typical Part Load Steam Consumption – Std. Unit 10 Typical Chiller Start-Up Performance 11 Typical Chiller Cooling Capacity for Required LCHWT 12 Typical Chiller Cooling Capacity for Avail. Steam Inlet Press.

13 Typical Chiller Steam Consumption for LCHWT 14 Steam Chiller Nozzle Arrangements 15 Hot Water Chiller Nozzle Arrangements 16 Unit Dimensions LIST OF TABLES TABLE PAGE 1 Enthalpy Values 2 YIA Chiller Shell and Tube Volumes 3 Generator Heat Loss (English) 4 Generator Heat Loss (Metric) 5 Approx. Insulation for Hot and Cold Surfaces (English) 6 Approx. Insulation for Hot and Cold Surfaces (Metric) 7 Nominal Ratings, Steam Machines (English) 8 Nominal Ratings, Steam Machines (Metric) 9 IPLV Analysis 10 Fouling Factor 11 Evaporator Pass Arrangements 12 Absorber / Condenser Arrangements 13 Hot Water Generator Nozzle Arrangements 14 Electrical Ratings Please Download Kindly Bookmark this Post using your favorite Bookmarking service.

. Cookie Consent We use cookies to improve your website experience.

To learn about our use of cookies and how you can manage your cookie settings, please see our. By continuing to use the website, you consent to our use of cookies. Welcome to HVAC-Talk.com, a non-DIY site and the ultimate Source for HVAC Information & Knowledge Sharing for the industry professional! Here you can join over 150,000 HVAC Professionals & enthusiasts from around the world discussing all things related to HVAC/R. You are currently viewing as a NON-REGISTERED guest which gives you limited access to view discussions To gain full access to our forums you must; for a free account. As a registered Guest you will be able to:.

Participate in over 40 different forums and search/browse from nearly 3 million posts. Post photos, respond to polls and access other special features. Gain access to our free AOP (Ask a Professional) Section to get real answers for your questions. All this and much more is available to you absolutely free when you; for an account, so today!

We suggest not registering using an AT&T, BellSouth, AOL or Yahoo email address. If you have any problems with the registration process or your account login, please. It has gotten worse as the day has gone on only getting to 52 degree chilled water. I have purged system well bubbles have stopped.

I took these chillers over from an old timer who retired about three years ago. He taught me what he could in the little time I got to work with him. Never had to make any decent repairs at that time. Repaired a large leak last year but besides that havent had any issues with it.

Two samples ago it showed high copper from the leak, so we aerated the solution and filtered it down to 1 micron b4 putting it back into the machine. Before we did so it was still doing what it is now.

The last sample showed a minimal amount of copper. Everything I have read tells me maybe something is restricting my flow from the generator to the heat exchanger causing solution to bypass through the j tube? Mnfitter' Assuming no-one has removed some refrigerant for whatever reason, it sounds like the heat exchanger is still partially rocked up to the point that the 'Auto-decrystallization' will not get it done. Dumping the refrigerant and reducing the steam input for a while might break it loose albeit you will be heating your chill water supply during this period of time. Manually 'DE-crystallizing' is a hairy process to say the least without heating your chilled water supply.

The process involves so many things that must be done at the same time to heat the 'Entire' heat exchanger(Without a damn rosebud torch) that it would take several pages of what and when to do certain things that I would hesitate even starting. My best advice is for you to get an experienced absorber man(York) and try and follow his every move during the process. Until such time that the 'Entire' heat exchanger is heated to around 200°f there will always be the chance that the heat exchanger is still rocked-up or partially crystallized.

I wish you well in whatever you decide. Are you positive it is stacked? We have a 25 year old single stage York ( ES model, think YIA with pneumatic controls) and it has had this same condition for the past 4-5 years. An overflow pipe that is too hot to leave your hand on but it is not crystallized.

Maybe yours is not either. We have looked for blockages and found nothing. The absorber/condenser tubes on this machine are heavily scaled, 25 - 30 degree condenser approach temp. And I think this maybe the crux of the problem. Maybe ( in our machine) the generator section is running too hot and creating enough pressure to blow out the liquid seal in the overflow line and when it does it allows hot vapor to flow through the pipe, heating up the sensor and putting it into autodecrystallization.

Otherwise this machine runs, will chill 5-6 degrees & the level in the sight glass is normal. This machine is far from perfect and should have the tubes acid cleaned but due to past bad experiences with this machine we are just waiting to replace it in one more year. Re your machine I do not have a quick easy answer. Are you positive it is stacked? Is there no level in the sight glass? Is it not chilling at all?

Next time it goes in to autode. Try pulling the sensor in the overflow, let it get out of autode. And let it run. If it maintains a good level in the sight glass and keeps chilling you are not stacked. If it is stacked then pull some LiBr samples when it is running good and at full load.

Get an equilibrium chart and plot the weak sample and determine the refrigerant temp. That goes with it. Your refrigerant temp should be within 3 degrees F. If it is greater than that, there is air in the machine. Maybe vac pump needs attention.

Determine the strong LiBr concentration. I would expect it to be 64.5% or greater. If so the machine should be spilling. If it is not spilling then it needs more refrigerant water. Years ago I cut open the end of the heat exchanger where the dilute LiBr enters and found the ends of the tubes plugged with debris.

York stretches a spring inside these tubes end to end, to create turbulence, and this was enough to act as a strainer. If flow is an issue it is not necessarily somewhere after the strong solution line. I hope in your case there is air in the machine. Like I said we never determined the problem with ours. I don't think it is rocked up.

Switched back to trouble machine thiis morning. Pulled down to about 45 and steam valve started backing down. Removed sensor like you stated and as it continued to get off setpoint valve opened up and is maintaining 44 degree water with no issues.

When steam valve was at its lowest and demand was low was when my decrystallization temp in the j tube started coming up. I do need to add inhibitors was waiting until I could get it running good to do so. Octyl alcohol, would I have lost this when we filtered out the solution? I do not have an answer as to exactly what is going on but at least you do not have a stacked machine and you have a machine that can function in the meantime. I have 4 YIAs running today and I compared the overflow pipe temps. Three of them were identical, the temp at the bottom of the u-shaped pipe was the same as the dilute solution and going up, above the temp sensor well, it went up to about 110 degrees F.

The 4th machine was more like yours. It was running at a light load, 20% steam valve, but at the bottom it was 20 degrees warmer than the dilute and above the sensor it was about 140 and seemed to track the same temp as the strong solution line. As you described, I lowered the setpoint and the machine started working harder and now after an hour of running the temps in the overflow have come down and closely match the other 3. So is this machine overflowing a little bit? Maybe, but not being able to see inside makes it hard to be certain. Unlike your machine this one has not tripped the temp sensor but maybe it has been close at times. To answer some of your questions, yes spilling is when the evaporator pan overflows.

On a YIA look in one of the 2 sight glasses on the end of the machine and look for water to be pissing out of the hole about a half inch below the top of the pan. If it is overflowing the top of the pan it is really spilling. You should not see this until your strong solution is at least 64.5 to 65%. If it is happening sooner you are being robbed of refrigeration capacity. Do not rely on the concentration being shown on the control panel until you verify with actual samples that it is showing the correct concentration. Do not add any refrigerant until you know it is reaching 65% and not spilling. Go ahead and add the inhibitor but I doubt that will change a thing.

Same with the alcohol. When you filter, alcohol will get trapped in the filter but it can be added back to the machine. To check for alcohol, flush your sampling valve and then remove a pint or so of LiBr, if you can see alcohol floating on the surface there is enough. If you are not certain add a quart, but I have yet to see more alcohol solve anything.

Welcome to on the job learning that goes with absorbers, have yet to find a textbook on these things. Read all the manuals you can find, you never know where you will find little nuggets of knowledge. York/Johnson Controls has quite a bit of info available at cgproducts.johnsoncontrols.com, go there and enter YIA in the search box and you will find all kinds of info. Mnfitter - I have an educated guess about what is going on with your overflow line. I think the solution pump is pumping too much at times.

Just as you observed the line heats up when the demand is low and cools down when it is high. I have spent the past day observing, temp taking and playing with 2 side by side YIAs and have seen exactly what you described. Maybe the following causes the overpumping. When the demand is low the LiBr level is highest in the absorber section which would slightly increase the suction head. Also the LiBr specific gravity is lower making it a little lighter and the pressure in the generator is a little lower creating a little less back pressure.

I think all of these are enough to increase the flow from the pump and cause the LiBr to just start to overflow. When the demand picks up and all of these reverse, the flow decreases enough to not overflow. I think if we could see inside the strong solution line it would always be near the inlet to the overflow pipe and this is the nature of the beast.

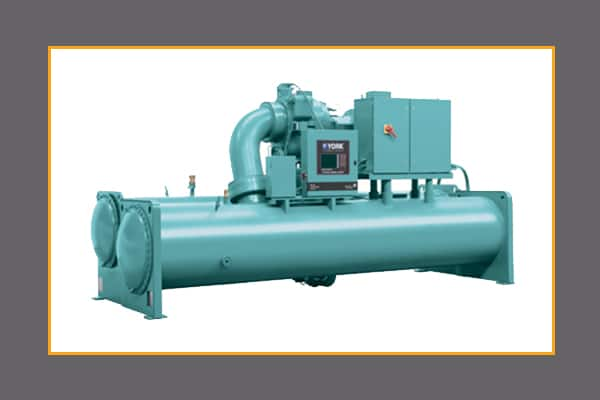

York Absorption Chiller Literature

When it was overflowing a little it is not filling the overflow line it is just flowing in along the bottom of the pipe. I used an infrared thermometer to confirm this, if you do not have one get one.

I have to assume this has always been going on with my machines but I have never paid this much attention to the overflow line. Quick Navigation. Site Areas.

York Absorption Chiller Service Manual

Forums.