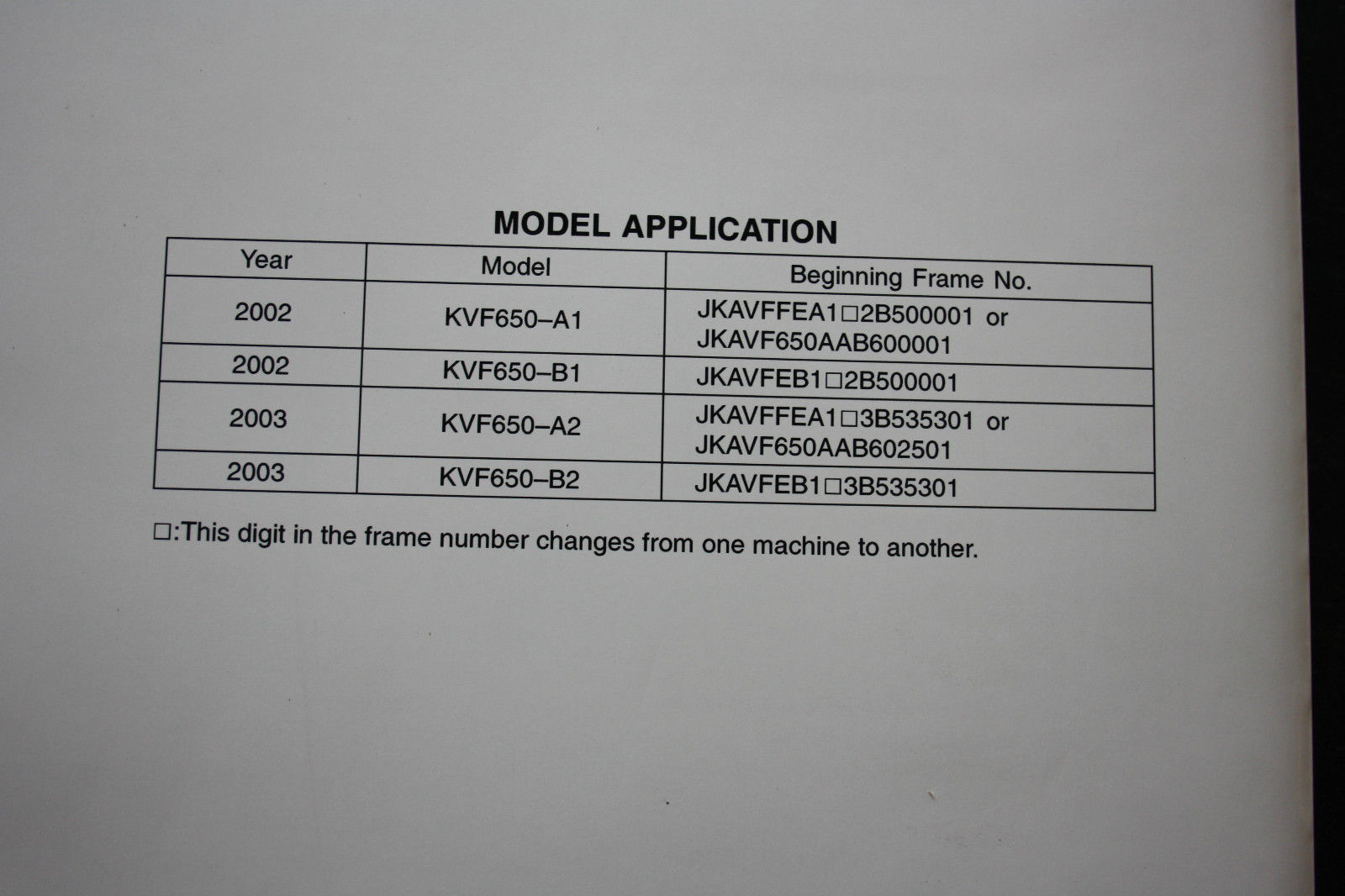

Manual Prairie 650 4 X 4

Ok guys I took it all back apart so I can show ya'll how I did it. We will start with a parts list. Local hardware store items 2- locking hasps 1- 1/4-20 x 2 1/2 bolt (grade 5) 1- 1/4-20 x 1/2 bolt (grade 5) 2- 1/4-20 nuts (grade 5) 4- 1/4 washers 1- 1/4 lock washer 1- 1/4-20 coupling 3- #6-32 x 1 1/4 screws 6- #6-32 nuts 6- #6 lock washers 1- 5/16 x 1 steel spacer 1- 5/8od x 5/16id rubber grommet ebay items 1- 4wd selector off 07 Honda rancher 420 1- spring off Honda 4wd cable 1- rear parking brake cable off 07 can-am spyder Ok I know the pics aint the best and the brute is dirty but I did some test riding and didn't clean it for the pics. Besides they look better dirty Step 1: Completely gut your actuator and smooth out the inside. I used a 1/2 drill bit to east down the taps inside the case and a rasp file to make the indention in the bowl are and 4 notches for the hasp (you'll see why later) Step 2: The cable I used has 5/16 threads on it so i drilled 3/8 hole angled slightly up Step 3: Place your top hasp on your case with the end closes to the hole you drilled sitting just inside outer edge and mark where your notches go that I pointed out in step 1. Also figure out where you have to cut your hasp for the length and angle on the back.

Be sure to only cut it enough so that it sits snugly in your notches when you make them (sorry I didn't take a pic of just the hasp) Step 4: Time to make the bottom hasp. I took my top hasp and lined the slot up with the bottom hasp and clamped them together then drilled my 3 holes for the #6-32 screws to go in. I only use these screws as spacers and guides not as mounts. After you have the holes drilled unclamp them and cut the end closes to your casing hole all the way back to the slot beginning.

Then trim the rest of the hasp to fit snugly in the case and install your screws with 2 nuts and 2 washers on each screw as I did then place top hasp on them and cut screws flush with the top. Then fit it all in the case and drill a hole that goes all the way through both hasp and case. Make sure the hole goes inside the motor housing so that it stays water proof. Step 5: Time to make the pin. I took my 2 1/2 grade 5 bolt and put the threaded end in my drill careful not to tighten down to much on the threads and took a triangle file and held it to the bolt as it turned in the drill to make the grove for the collar and pin to sit in.

Next cut your head of the bolt off and 1/8 from the center of your grove. Now stick the gear the collar was on back in the hole and measure how far it sticks out and right that down because you'll need it soon. Step 6: Take the 1/4-20 coupling, 3 washers, 1 lock washer, and the 1/4-20 x 1/2 bolt and screw the bolt and washers to the coupling and put your hasp together, then stick the coupling through the slots on the hasp and your gonna want to cut the coupling so that 1/16 sticks out past the hasp slots on one end.

This is so when you tighten it all up when your done it leaves enough play to slide freely. Next cut a the over hang of the washers off flush with the coupling on one side. After you cut the coupling it is time to take your pin and place a jam nut and flat washer on it. Stick the coupling in your hasp slot and screw your pin in the other end. Put your hasp in your case and place the aluminum bottom on the case. Now measure how much of your pin sticks out and then subtract how much the old gear stuck out.

Kawasaki Prairie 650 Manual 4x4 Conversion

This is how much you need to cut off your threaded end of your pin. Now pull the case back apart and drill a 1/8 hole just off center of the coupling towards the 3/4 bolt side. Be sure to drill it from the side you cut the washers.

Step 7: Modifying the cable. Take the cable and on the side that has the longest threads cut the cable off to where there is 2 1/2' of cable sticking out past the threads.

Before you cut it make sure you have the opposite end that has the metal stop is connected to your lever and is in the 2wd position. Once you cut the cable pull it out of the guide casing. Now remove the hooded nut from the long thread side and swap it with the regular nut from the short thread side then put the cable back in the way it came out. After that trim back the Teflon coating that is on the cable about 1'. Next put your cable in your actuator case with the rubber grommet and washer and assemble the hasps, coupling, and pin together. Your pin and your 1/2 bolt in the coupling acts as a sandwich for the cable so that it does not slip out. At this time do not tighten down to much on the cable because this is only a mock up so that you can see what angle your cable needs to go into the actuator case.

Once u figure out your angle you will take the 5/16 spacer and cut the angle into it so that when you have your finished product fully tighten it will hold your angle for you. Step 8: Now that you have your angle mocked up, before you disassemble everything in your case, hook your cable to your shifter and make sure it slides good with the angle you made.

Now put the aluminum bottom on the case. Shift your lever into 2wd and make sure the pin slides all the way and touches the aluminum wall (this is a must for it to disengage 4wd) then shift it into 4wd and make sure it comes no more than a 1/4' from the aluminum wall on the cable side.

After all this is right, place it in 4wd and measure from your coupling to the nut holding your cable in the case. This is the compressed length of your spring. Now take your spring compress it and cut it to your measured length. Step 9: Put assembly back together with all components including your spring, check and make sure it still slides well and that the 2wd position is against the wall.

Once all is correct install the complete unit on the front diff and crank your brute (best if on jack stands to make sure its engaging correct) and test 2wd and 4wd position. You should not have to rotate front wheels like the old electronic actuator did. Then pull back off, remove aluminum bottom and motor housing and seal with rtv. Do not forget to seal everything well including the old wiring harness hole, reuse harness grommet if you have it Step 10: After everything checks out ok route your cable to the left side of your brute. Next I lined up my 2wd/4wd selector with my gear selector so that when my gear selector is in neutral and the 2wd/4wd selector is in 2wd they are even and marked the location.

Take the black trim piece off the selector and trim off taps that i point out in the picture. Then start cutting out little by little of your panel till the trim piece sits flat.

Then install lever bracket back on trim piece while on the panel. Drill 2 1/4' holes and place bolts an washers. Now install cable to selector and enjoy trouble free instant 4wd.

I've been up riding and camping along the Paiute since last Thursday (still up here). I've put over 400 miles on the ATV since arriving. An odd thing has started though. The 2WD/4WD indicator has now started alternating 2WD / 4WD. Does this indicate something?

I have extra air filters, spark plugs and have done routine maintenance, but am wondering if this alternating thing signifies something specific? Oh, anyone up this way between now and Sunday (Kimberly Road, off Spidertrails 15 and 76. Come say hello! After I made the post I realized my manual for my BF 650 was sitting next to me. Any way this is what it says about the flashing back and fourth: Flashing 2wd/4wd indicator light signals a malfunction of the kawaski engine brake control system or the selectable 2WD/4WD system. A flashing interval of 0.5 seconds indicates a malfunction with the 2WD/4WD actuator, a 1 second interval indicates the kawaski engine brake control actuator is Malfunctioning, and a 2 seconds interval if both actuators are malfunctioning.

Prairie 650 Manual 4x4 Actuator

Whichever the case may be, see an authorized kawaski dealer for repair. Hope this helps you out.

Several years ago I took my old red 650i down a 30 foot snowbank, and I mean straight down. The front diff split open and I was done for the day.

Kawi fixed it under warranty even though the warranty period was passed. The dealer never replaced the front actuator while the repair was made. It went back and back and back and no one could figure out what was wrong. The service manager somehow ended up with another job.

I now have a factory service manual. The coils have specific ohm readings and you can tell which one is bad. You can also have a bad connection. Be sure to clean them all out. We know how you ride. This forum takes a lot of money to keep it going with hardware, software and connection costs.

Help me keep this forum going with a donation. Thank you for your support and help, but I could definitely use a lot more. To donate using a credit card through PayPal, click the the PayPal button below. If you prefer to not use PayPal, send the Admin a PM. All Rights Reserved. Please note your IP address has been logged; any abuse will be reported to the appropriate authorities.